Comprehensive Guide to Lens Performance Testing

Comprehensive Guide to Lens Performance Testing:

Overview of 11 Core Projects, Supporting Equipment, and Environmental Requirements

In today's digital era, lenses have become core components of numerous devices, including smartphones, security surveillance systems, video conferencing equipment, and intelligent transportation systems. The quality of lens performance directly impacts user experience and product value. This article provides a comprehensive analysis of key projects and methods for lens performance testing, offering a practical reference for manufacturers and quality control teams.

1. Reverse Projection Resolution Analysis

This method is primarily used to evaluate the resolving power of the lens. In operation, a projector projects a test chart image onto a diffuse reflection screen in a darkroom. The lens under test is then adjusted to align with the screen and present the clearest image. Imaging quality is evaluated by observing the sharpness of the image with the human eye. Although this method relies on subjective judgment, it is highly efficient and provides reliable references when processing large volumes of samples.

Key Equipment:Projector, diffuse reflection white screen, fixing fixture.

Test Environment:Optical darkroom required, with ambient illuminance below 1 lux to avoid stray light interference.

2. Resolving Power Test (MTF Test)

The MTF (Modulation Transfer Function) test objectively evaluates the resolving power and overall consistency of the lens by analyzing the module's modulation transfer function.

Key Equipment:MTF test chart, test jig, computer, and professional analysis software (such as Imatest or ISeetest).

Test Environment:Conducted in a test darkroom with a surface illuminance of 800±50 lux.

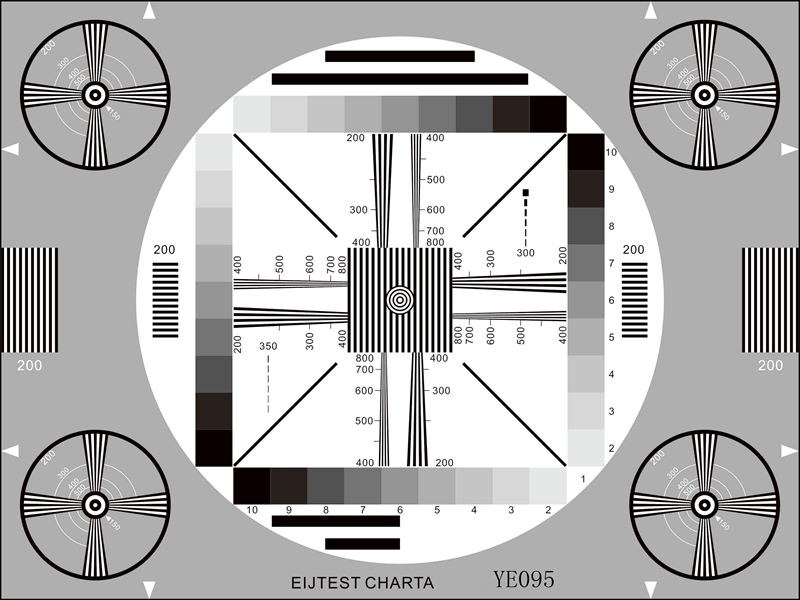

3. TV-Lines Test

This method involves shooting a specialized image test chart and using software to analyze the captured images, quantifying the lens resolution in terms of TV lines. This allows for direct comparison of shooting effects between different lenses.

Key Equipment:Image test chart, test light box, computer, and analysis software.

Test Environment:Test light box providing 800±50 lux illuminance.

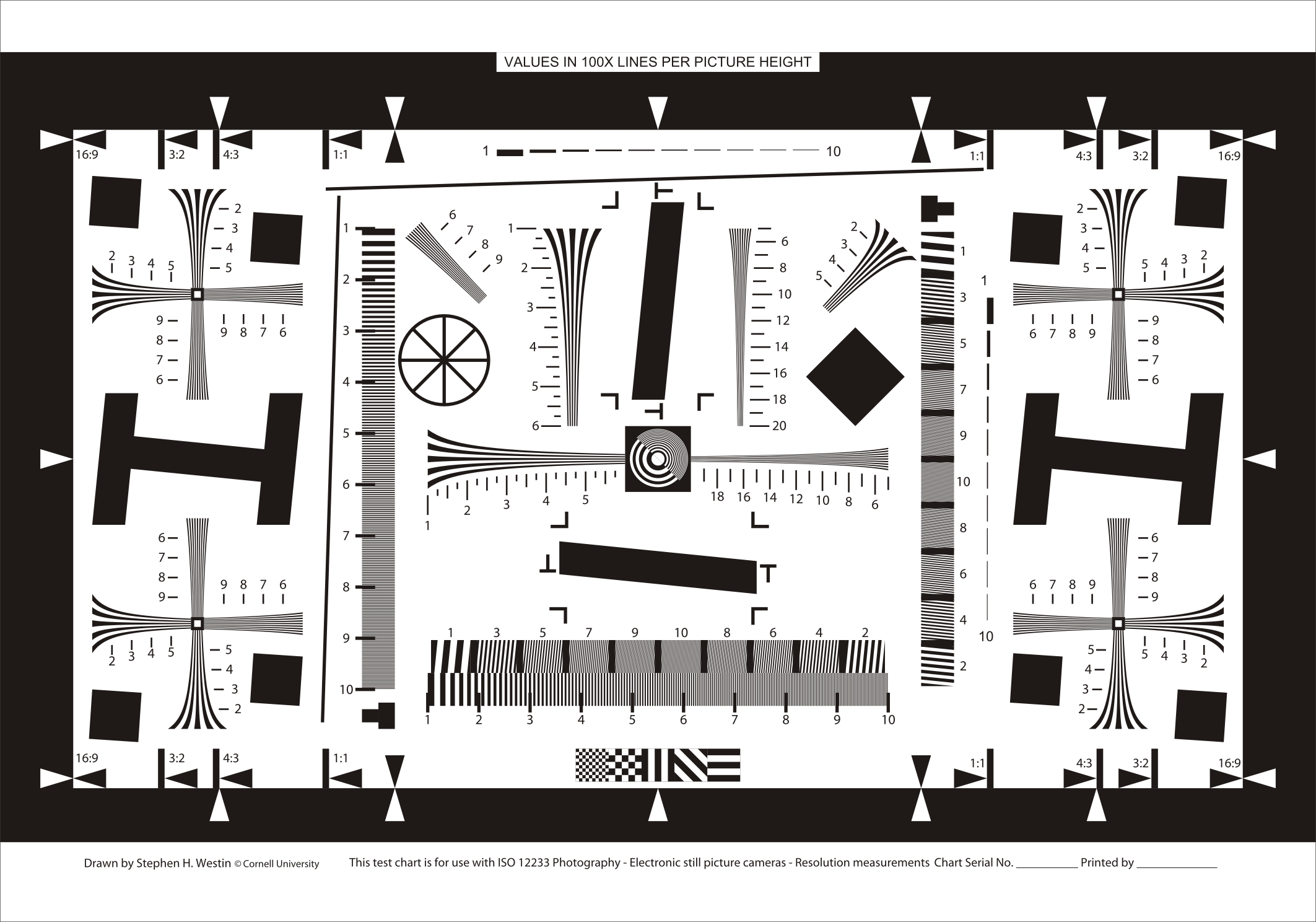

4. Resolution Test SFR/TV-Lines

This acts as a supplement and standardization for the TV-Lines test. It uses professional software (such as Imatest) to analyze images of the ISO12233 resolution test chart, reading SFR (Spatial Frequency Response) data to make more precise judgments on lens resolution.

Key Equipment:ISO12233 test chart (2000 or 2014 version), test darkroom, computer, and image quality analysis software.

Test Environment:Illuminance controlled at 800±50 lux.

5. Color Reproduction Capability Test

This test aims to evaluate the authenticity of the lens in reproducing colors. A standard 24-color chart is photographed under different standard light sources (such as DAYLIGHT, COOL WHITE, TL84/U30). Software then compares the values of the color blocks in the captured image with standard values.

Key Equipment:TILO color assessment cabinet (light box), standard 24-color chart, computer, and image quality analysis software.

Test Environment:Must be conducted under specified standard light source environments.

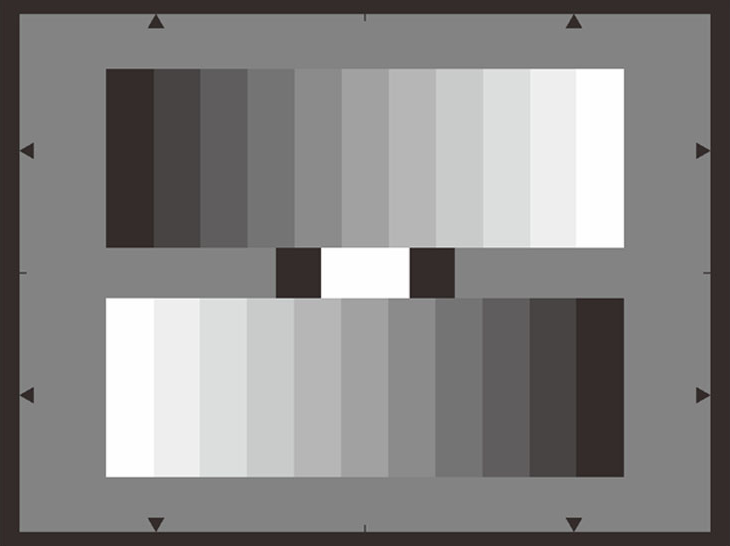

6. Gray Scale Resolution Capability Test

By photographing a gray scale test chart under different light source environments, this evaluates the lens's ability to distinguish between gray levels. The resulting images are analyzed to judge the gray scale resolution effect.

Key Equipment:TILO color assessment cabinet, gray scale test chart (such as EIA CHART), computer, and analysis software.

Test Environment:Usually conducted under light sources such as DAYLIGHT and COOL WHITE.

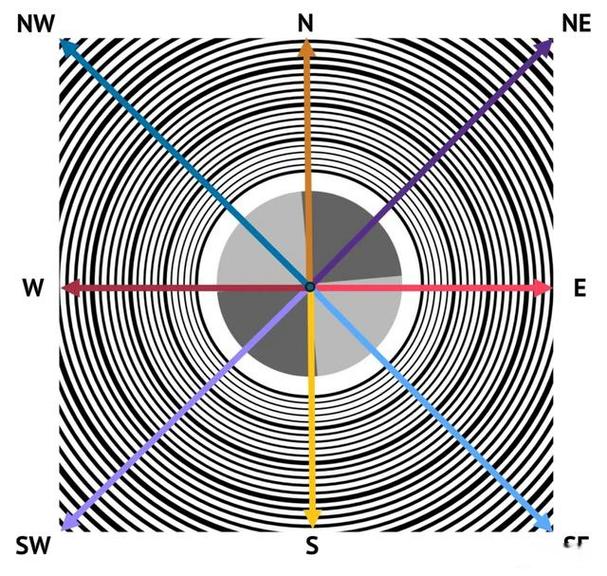

7. Relative Illumination Test (Shading)

An 18% gray card is photographed under uniform lighting conditions. By analyzing the ratio of brightness between the center and the corners of the image, the lens vignetting effect—i.e., the drop in brightness at the edges of the frame—is evaluated.

Key Equipment:Test darkroom, 18% gray scale test chart, computer, and lens quality analysis software.

Test Environment:Illuminance requirement is 600±50 lux.

8. Field of View Test (FOV)

By photographing an FOV chart (field of view test chart) at a specific distance and calculating/interpreting the image, the actual field of view angle of the lens and sensor combination is precisely measured.

Key Equipment:Test darkroom, tripod, FOV chart, computer.

Test Environment:Illuminance requirement is 600±50 lux.

9. Light Leakage and Ghosting Test (Flare)

This test is used to evaluate the lens's resistance to stray light under strong light conditions. A regularly arranged floodlight source is photographed in a darkroom to observe whether non-imaging halation phenomena such as ghosts or flares appear in the captured image.

Key Equipment:Floodlight source array, optical darkroom, test fixture.

Test Environment:Standard darkroom.

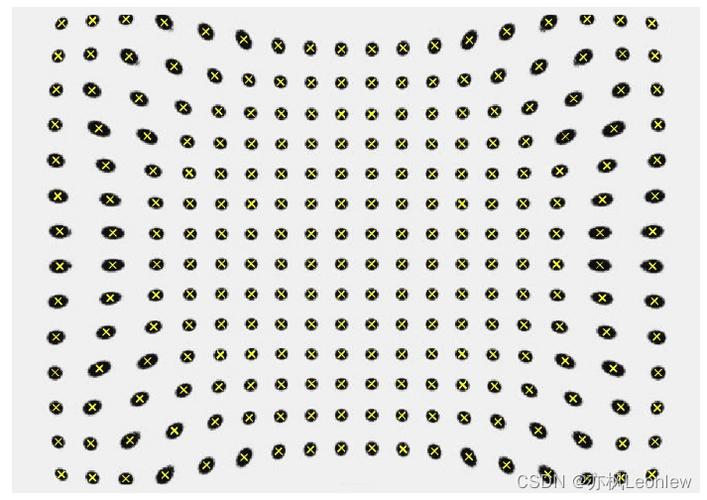

10. Image Distortion Test

By photographing a checkerboard test chart, the degree of geometric distortion in the resulting image—such as barrel distortion or pincushion distortion—is measured and calculated to evaluate the imaging fidelity of the lens.

Key Equipment:Test darkroom, distortion test chart (checkerboard card), test fixture.

Test Environment:Illuminance requirement is 800±50 lux.

11. Indoor/Outdoor Actual Shooting Test

This test focuses on evaluating the lens's performance in real-world application scenarios. The imaging effect is comprehensively judged by shooting under various actual lighting conditions (such as a sunny morning, dusk, or indoor fluorescent/incandescent light environments). Professional image testing laboratories can simulate these diverse lighting environments.

Key Equipment:Mobile test fixture, color temperature meter, illuminance meter (lux meter), etc.

Conclusion:

Comprehensive lens testing is key to ensuring product quality. Through the above test projects, manufacturers can fully evaluate lens performance, identify potential issues, and perform targeted optimizations. As technology evolves, lens testing standards and methods are also constantly updating. It is recommended that companies stay informed about the latest standards and refine testing processes to enhance product competitiveness. For industry applications with special requirements, corresponding industry standards—such as the GA/T1128-2013 standard for the security surveillance field—should also be referenced to ensure the reliability of the lens in specific usage environments.