Comprehensive Guide to Lens Selection and Parameters

In the realms of machine vision and high-end photography, the lens is the "eye" of the system. Even the most expensive camera sensor is rendered useless if paired with an inferior lens. Especially in industrial inspection, automated metrology, and precision assembly, selecting the correct lens is a critical factor determining the success or failure of a project.

Part 1: Deep Dive into Key Lens Parameters

Before selecting a lens, you must understand the technical specifications:

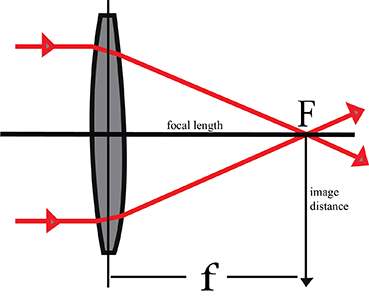

1. Focal Length (f)

Definition: The distance from the optical center of the lens to the image plane.

Impact: Determines the Field of View (FOV). A small number (e.g., 8mm) yields a wide angle; a large number (e.g., 50mm) yields a narrow angle (telephoto) but magnifies distant objects.

Industrial Use: Calculated based on Working Distance and required FOV.

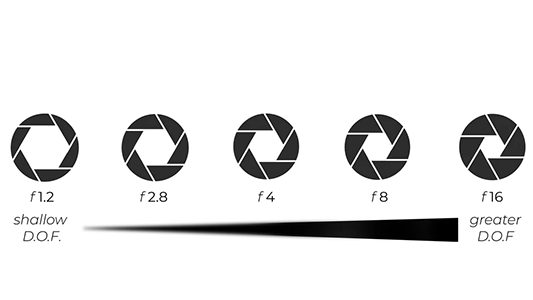

2. Aperture / F-Number

Definition: The size of the opening that lets light in. F-No = Focal Length / Entrance Pupil Diameter.

Impact: A lower F-number (e.g., F1.4) means a larger aperture (more light, shallow Depth of Field). A higher F-number (e.g., F16) means a smaller aperture (less light, deeper Depth of Field).

Industrial Use: Large apertures are needed for high-speed objects (short exposure). Small apertures are used when inspecting products with varying heights to keep everything in focus.

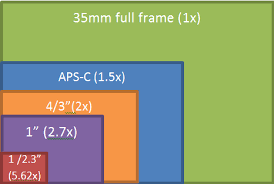

3. Sensor Size / Image Circle

Definition: The maximum diameter of the image the lens can project clearly.

Rule: The lens's image circle must be greater than or equal to the camera's sensor size.

Example: A 2/3" camera requires a 2/3" or larger (e.g., 1") lens. Using a 1/2" lens on a 2/3" sensor will cause vignetting (dark corners).

4. Mount

Common Types:

C-Mount: Standard industrial mount, 17.526mm flange distance.

CS-Mount: Common in CCTV, 12.5mm flange distance (requires a 5mm spacer to fit C-mount cameras).

F-Mount: Nikon standard, used for large sensor Line Scan cameras.

Our company only manufactures S-mount lenses.

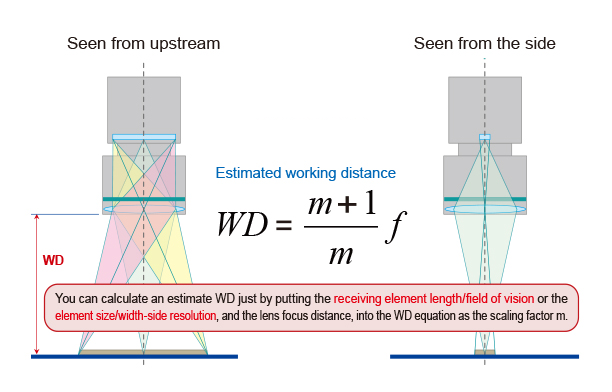

5. Working Distance (WD)

Definition: The distance from the front of the lens to the object.

Note: Standard lenses have a minimum object distance (MOD). Macro and Telecentric lenses are often designed for a fixed WD.

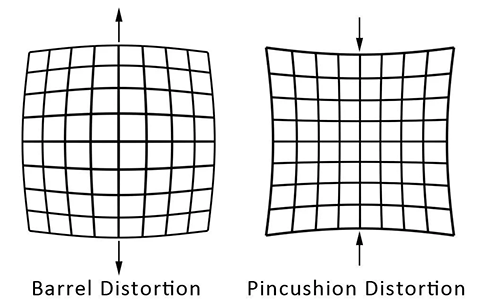

6. Distortion

Definition: Geometric aberration where straight lines appear curved (Barrel or Pincushion).

Industrial Importance: For Gauging/Measurement applications, low distortion lenses (<0.1%) are mandatory. Otherwise, the measurement data will be inaccurate.

7. Resolution (MTF)

Definition: The ability to resolve detail, often measured in line pairs per millimeter (lp/mm) or Megapixels (MP).

Rule: The lens resolution should match or exceed the pixel size/density of the camera sensor.

Part 2: Categories of Industrial Lenses

Different industrial applications require specific optical designs:

1. FA Lens (Fixed Focal Length / CCTV)

Characteristics: General-purpose, affordable, variable focus and iris. Typical distortion 1-2%.

Application: Defect detection, barcode reading, robot guidance (where extreme precision is not required).

2. Telecentric Lens —— The King of Measurement

Problem Solved: Eliminates the perspective error (parallax) found in standard lenses (where close objects look bigger).

Characteristics: Principal rays are parallel to the optical axis. Magnification remains constant even if the object moves closer or further within the depth of field.

Application: Precision metrology, pin inspection, imaging multi-layered objects.

3. Macro Lens

Characteristics: Designed for short working distances, high magnification, and low distortion.

Application: Chip inspection, PCB solder joint inspection.

4. Line Scan Lens

Characteristics: Large image circle (45mm - 80mm+), designed for line scan sensors.

Application: Web inspection (paper/foil), glass inspection, conveyor belt sorting.

Part 3: Step-by-Step Selection Guide

The Core Formula:

f=WD×V/Vfov

(Where: f=Focal Length, WD=Working Distance, V=Sensor Vertical Size, V_fov=Vertical Field of View)

Selection Process:

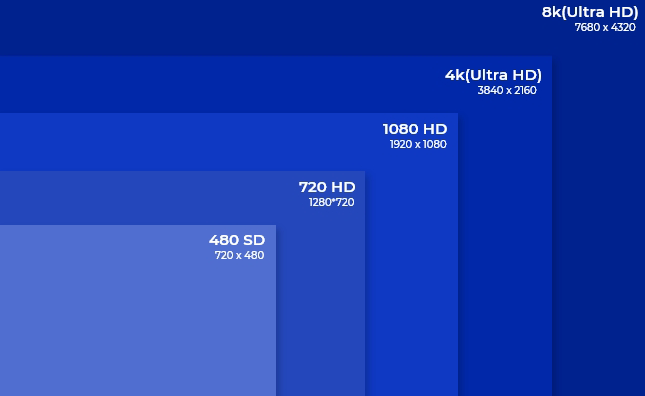

Identify Sensor Size:

Choose your camera first. Is it 1/3", 1/2", or 2/3"?

Example: A 2/3" sensor has dimensions approx. 8.8mm x 6.6mm.

Define Field of View (FOV):

How large is the area you need to see?

Example: The product is 100mm x 80mm.

Determine Working Distance (WD):

How far must the camera be from the part due to mechanical constraints?

Example: The mount is fixed at 500mm away.

Calculate Focal Length:

Using the formula:

f=WD×(Sensor Width/FOV Width)

f=500×(8.8/100)=44mm

Selection: Standard fixed focal lengths are 35mm, 50mm, etc. A 50mm lens would provide a smaller FOV (zoomed in), so a 35mm lens is the safer choice to ensure the whole product fits in the image.

Verify Resolution & Distortion:

If your camera is 5MP, ensure the lens is rated for "5MP".

If performing measurements, request the distortion chart from the manufacturer. For high precision, consider a Telecentric Lens regardless of the calculation above (Telecentrics are selected by Magnification, not Focal Length).