Deciphering Industrial Fixed Focus Lenses: From Parameter Analysis to Selection Guide

Fixed Focus Lenses, as the name implies, are lenses with a fixed focal length. Their most significant characteristic is a fixed Angle of View (AOV). Unlike the zoom lenses common in daily life, industrial fixed focus lenses focus at different working distances by moving all lens elements as a whole, while maintaining a constant spacing between the individual lens elements.

This unique design mechanism grants fixed focus lenses three distinct advantages:

Simple and stable structure:Reduces the risk of failure caused by complex mechanical structures.

Fast focusing speed:Improves inspection efficiency in industrial production.

Stable imaging quality:Ensures the reliability and consistency of measurement results.

For these reasons, fixed focus lenses are highly favored in demanding industrial scenarios such as machine vision, precision measurement, scientific imaging, and long-distance monitoring.

This article provides an in-depth yet accessible analysis of the key technical parameters of industrial fixed focus lenses, revealing the optical principles behind them, and offers a practical selection guide to help you make the best choice among numerous products.

I. Understanding Focal Length

1. Focal Length

Focal length is the most fundamental technical parameter of a lens. It is defined as the linear distance from the optical center of the lens to the imaging plane (camera sensor surface), usually measured in millimeters (mm). This parameter directly determines the lens's field of view and the size of the image, making it the primary consideration in lens selection.

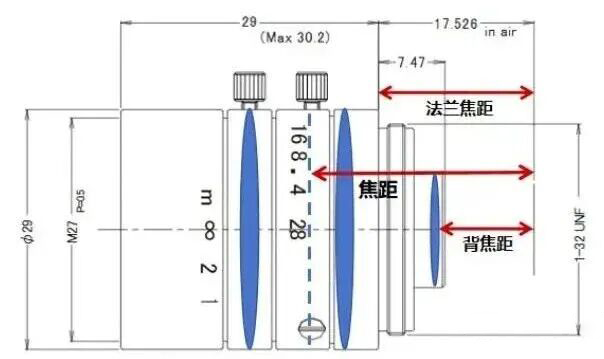

2. Flange Focal Distance (FFD)

Flange focal distance specifically refers to the physical distance from the mounting flange of the lens (the contact surface between the lens and the camera body) to the camera sensor surface. This parameter is critical for lens interface compatibility, as different interface standards have different flange focal distance requirements.

3. Back Focal Distance (BFD)

Back focal distance is often confused with flange focal distance, but there is a clear distinction. BFD refers to the distance from the vertex of the last lens element to the imaging plane. This parameter directly affects the optical design and imaging performance of the lens.

These three focal length parameters constitute the basic framework of the lens's optical characteristics and must be considered comprehensively during the design and selection process.

II. Working Distance and Sensor Size: Key Performance Indicators

1. The Practical Significance of Working Distance (WD)

The working range of an industrial fixed focus lens is usually labeled in the format of "Minimum Working Distance ~ ∞" (e.g., "0.25m ~ ∞"). This indicates that the lens can achieve clear focus within the range of 0.25m to infinity.

The determination of the minimum working distance is not a simple mathematical calculation. It is a professional technical parameter determined by optical engineers through professional design software simulations of the light path, combined with physical limitations of the lens elements.

When the subject is too close to the lens, the angle of incident light becomes too large, exceeding the focusing capability of the lens group, making it impossible to form a clear image. This critical point is the minimum working distance.

Conversely, when the object is at infinity, the incident light is approximately parallel, allowing the lens to focus easily. This is a basic functional requirement of fixed focus lenses.

2. The Identification System of Sensor Size

The "Maximum Sensor Size" parameter labeled on an industrial fixed focus lens indicates the maximum sensor specification that the lens can fully cover and work with normally. Common labels such as 1/6", 1/2", and 2/3" originate from early video camera tube traditions. Although they no longer directly correspond to the actual physical dimensions of modern sensors, they have formed an industry-standard system.

Taking a typical 2/3-inch lens as an example, its actual imaging area is 8.8mm × 6.6mm, with a diagonal of approximately 11mm. When selecting a lens, you must ensure it supports the camera's sensor size; otherwise, issues such as vignetting (black corners) or degraded edge quality will occur.

Sensor size is usually represented by the diagonal length, following industry conversion standards. Below is a comparison table of physical dimensions for common specifications:

Specification | L × W (mm) | Diagonal (mm) | Applicable Standard | Typical Application Scenario |

1/3 inch | 4.8 × 3.6 | 6.0 | 1 inch = 18mm | Security Monitoring / Industrial Vision |

1/2.5 inch | 5.8 × 4.3 | 7.2 | 1 inch = 18mm | Mobile Secondary Cam / Dash Cams |

1/2 inch | 6.4 × 4.8 | 8.0 | 1 inch = 16mm | Industrial Inspection / Drone Vision |

1/1.8 inch | 7.2 × 5.4 | 9.0 | 1 inch = 16mm | High-end Mobile Main Cam |

2/3 inch | 8.8 × 6.6 | 11.0 | 1 inch = 16mm | Medical Imaging |

1 inch | 12.8 × 9.6 | 16 | 1 inch = 16mm | Professional Compact Cameras |

4/3 inch | 17.3 × 13.0 | 21.6 | Independent Std | Mirrorless Cameras |

III. F-Number and Resolution: The Core of Optical Performance

1. The Optical Meaning of F-Number

The F-number (F/#) is a core parameter describing the light-gathering capability of a lens, defined as the ratio of the focal length to the effective aperture diameter.

A smaller F-number value indicates a larger aperture opening and sufficient light intake.

Conversely, a larger F-number indicates a smaller aperture and limited light intake.

In industrial applications, the F-number is usually written as F/# (e.g., F/1.0, F/1.4, F/2.0, F/2.8, etc.). These numbers typically increase by multiples of √2. Because increasing the F/# by a factor of √2 reduces the lens aperture diameter by a factor of √2, the aperture area is halved, effectively halving the lens's luminous flux. This design makes exposure control more precise and convenient, adapting to different lighting environments.

2. Resolution Evaluation System

The resolution of a fixed focus lens characterizes its ability to resolve image details. There are two main methods of representation:

Line Pairs per Millimeter (lp/mm):Used by the traditional optical industry.

Megapixels (MP):More commonly used in the modern industrial vision field.

There is a clear mathematical relationship between resolution and pixel size:

Resolution (lp/mm)=1/2*Pixel Size

For example, a "2MP lens" indicates that its optical performance can fully support the resolution requirements of a 2-megapixel sensor. During selection, it is necessary to ensure that the lens resolution matches the camera's pixel level to fully utilize the system's performance.

IV. Field of View (FOV) and Angle of View

The Angle of View is often referred to as the Field of View (FOV) in optical engineering. The size of the angle of view determines the scope of the lens's vision. When describing the angle of view, it is usually divided into:

Horizontal Field of View (HFOV)

Vertical Field of View (VFOV)

Diagonal Field of View (DFOV)

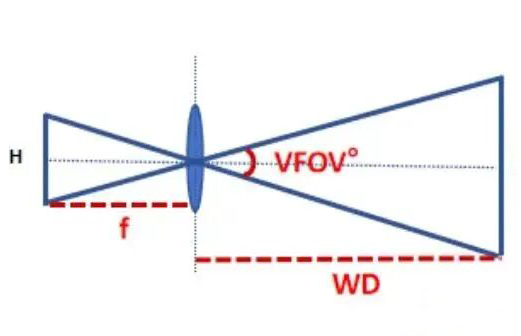

(Note: The text refers to a diagram showing the relationship between the sensor, lens, and FOV).

The Angle of View is inextricably linked to the fixed focus lens's focal length,working distance,imaging area height (sensor size), and vertical field height range.

Ideally (when sensor size is constant):The shorter the focal length, the larger the angle of view; the longer the focal length, the smaller the angle of view.

Taking the vertical angle of view as an example, its calculation involves the relationship between the focal length (f), the working distance (WD), and the sensor dimension. In many selection applications, the distance to the object being imaged, the required field of view (vertical field range), and the sensor size used (imaging area height) are known quantities. To select a suitable lens based on this, calculations can be performed using standard optical formulas (e.g., f=Sensor Height * WD / FOV Height).

V. Interface Standards and Selection Practice: Ensuring System Compatibility

1. Detailed Interface Standards

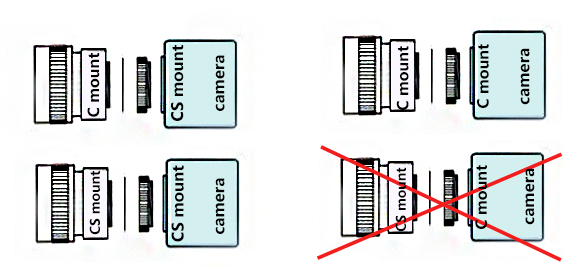

The industrial field mainly uses two standards:C-mount and CS-mount.

C-mount has a flange focal distance of 17.526mm.

CS-mount has a flange focal distance of 12.5mm.

Although the thread diameter is the same, the difference in flange focal distance determines their compatibility:

A C-mount lens can be used on a CS-mount camera by adding a 5mm adapter ring.

A CS-mount lens cannot be used on a C-mount camera via a simple adapter because the flange focal distance is too short, which would prevent focusing.

This detail requires special attention during system integration.

2. Practical Selection Guide

In the actual selection process, the following factors need to be considered systematically:

Focal Length: Determine the required focal length based on the inspection Field of View (FOV) and Working Distance (WD).

Resolution: Choose the appropriate resolution level based on inspection accuracy requirements.

Sensor Compatibility:Confirm compatibility with the camera sensor's size.

Interface:Check the matching of the optical interface (C/CS mount).

Conclusion

As a key component of machine vision, the technical level and application of industrial fixed focus lenses directly affect the quality and efficiency of intelligent manufacturing. We hope that this systematic interpretation helps readers establish a basic understanding of industrial fixed focus lenses and provides strong support for equipment selection and system integration in practical work.